average cnc machine shop rate The CNC machine hourly rate calculator helps shops estimate the costs of CNC machining jobs accurately. By considering various factors such as total cost of ownership, operator rate, working hours per day, downtime . What is the Standard Thickness of Sheet Metal? In Australia, the typical thickness of sheet metal is between 0.5 millimetres and 6 millimetres. Anything thicker 6 millimetres is classified as metal plate, and anything thinner than 0.5 millimetres is classified as metal foil.

0 · machine shop hourly rate calculator

1 · machine shop hourly rate

2 · how expensive is cnc machining

3 · cnc machining hourly rate

4 · cnc machining cost

5 · cnc machine hourly rate calculator

6 · cnc cutting cost

7 · calculating machine cost per hour

Junction boxes protect the electrical connections from the weather, as well as protecting people from accidental electric shocks. A small metal or plastic junction box may form part of an electrical conduit or thermoplastic-sheathed cable (TPS) wiring system in a building.

100/hr is pretty reasonable for "normal" work that requires normal sized machines. It sounds like you have the market cornered, so you might as well make a .

airtight metal boxes 7 gallons

According to a recent survey by Practical Machinist, the average hourly rate for a CNC machine is around . However, rates can range from to per hour, depending on the factors . The CNC machine hourly rate calculator helps shops estimate the costs of CNC machining jobs accurately. By considering various factors such as total cost of ownership, operator rate, working hours per day, downtime . The mainly CNC shop I worked in in the early 80's had a base rate of .00 for manual and 5.00 for CNC. The key word is base. That rate would vary up a lot or slightly .

machine shop hourly rate calculator

In my area, low end work is /hr, 5 axis is 0/hr. Average CNC work is 0/hr. a shop i work with quotes labor at 75/hr, not sure about machine time. In production manufacturing, my shop . Shop rate should be adjusted to each piece of equipment and their production rate and what not. If you had to buy a brand new 0-500K horizontal today, /hr for 40hr/week .

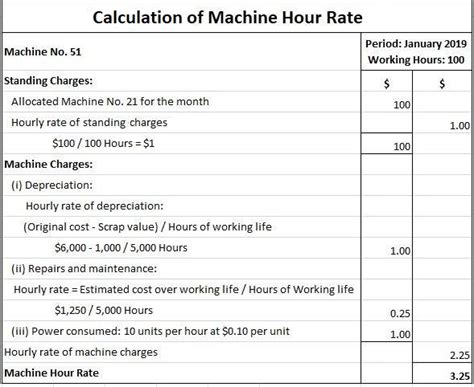

Two factors influence machining expenses: the upfront cost of a CNC machine and its expected yearly usage, typically around 5000 hours. Machinists determine machine shop rates, commonly known as the machining .In this guide, we have explored the various factors that influence CNC machine shop rates and discussed different pricing models that manufacturers may employ. Additionally, we have .General Machine Shop Hourly Rate . a common formula : Average overall shop rate = (average machine cost per hour + labor and overhead cost per hour) x markup. Machine Specific Hourly Rate . a common formula : (specific .100/hr is pretty reasonable for "normal" work that requires normal sized machines. It sounds like you have the market cornered, so you might as well make a decent profit off of it. In my experience there isn't an "average shop rate" for shops that handle oversize and heavy parts.

machine shop hourly rate

how expensive is cnc machining

According to a recent survey by Practical Machinist, the average hourly rate for a CNC machine is around . However, rates can range from to per hour, depending on the factors above.

60 to 80 dollars per hour is the average machine shop rate in most parts of the U.S.. Electricity is and overhead costs play an important role in what a shop is charging. However, the most important factor would be quality and type of shop. Prototype and short run parts are expensive due to set-up times.

The CNC machine hourly rate calculator helps shops estimate the costs of CNC machining jobs accurately. By considering various factors such as total cost of ownership, operator rate, working hours per day, downtime percentage, and markup, the calculator provides a reliable hourly cost estimate.

The mainly CNC shop I worked in in the early 80's had a base rate of .00 for manual and 5.00 for CNC. The key word is base. That rate would vary up a lot or slightly down depending upon the complexity of the parts, tolerances, the quanity, would it be a repeat job, and if you were a personal freind of the boss. In my area, low end work is /hr, 5 axis is 0/hr. Average CNC work is 0/hr. a shop i work with quotes labor at 75/hr, not sure about machine time. In production manufacturing, my shop makes its own products and based on each machine it's between 75-95 prior to overhead and part markup. Shop rate should be adjusted to each piece of equipment and their production rate and what not. If you had to buy a brand new 0-500K horizontal today, /hr for 40hr/week would not pay the term and tooling. Either way, either way the part price is . Two factors influence machining expenses: the upfront cost of a CNC machine and its expected yearly usage, typically around 5000 hours. Machinists determine machine shop rates, commonly known as the machining charge per hour, by dividing the price of CNC machines by their total yearly usage hours.

In this guide, we have explored the various factors that influence CNC machine shop rates and discussed different pricing models that manufacturers may employ. Additionally, we have provided valuable insights into optimizing costs and shared real-life case studies showcasing successful cost reduction strategies.General Machine Shop Hourly Rate . a common formula : Average overall shop rate = (average machine cost per hour + labor and overhead cost per hour) x markup. Machine Specific Hourly Rate . a common formula : (specific machine (s) cost per hour + labor + overhead cost per hour) x .

100/hr is pretty reasonable for "normal" work that requires normal sized machines. It sounds like you have the market cornered, so you might as well make a decent profit off of it. In my experience there isn't an "average shop rate" for shops that handle oversize and heavy parts.According to a recent survey by Practical Machinist, the average hourly rate for a CNC machine is around . However, rates can range from to per hour, depending on the factors above.

60 to 80 dollars per hour is the average machine shop rate in most parts of the U.S.. Electricity is and overhead costs play an important role in what a shop is charging. However, the most important factor would be quality and type of shop. Prototype and short run parts are expensive due to set-up times. The CNC machine hourly rate calculator helps shops estimate the costs of CNC machining jobs accurately. By considering various factors such as total cost of ownership, operator rate, working hours per day, downtime percentage, and markup, the calculator provides a reliable hourly cost estimate. The mainly CNC shop I worked in in the early 80's had a base rate of .00 for manual and 5.00 for CNC. The key word is base. That rate would vary up a lot or slightly down depending upon the complexity of the parts, tolerances, the quanity, would it be a repeat job, and if you were a personal freind of the boss.

In my area, low end work is /hr, 5 axis is 0/hr. Average CNC work is 0/hr. a shop i work with quotes labor at 75/hr, not sure about machine time. In production manufacturing, my shop makes its own products and based on each machine it's between 75-95 prior to overhead and part markup.

cnc machining hourly rate

Shop rate should be adjusted to each piece of equipment and their production rate and what not. If you had to buy a brand new 0-500K horizontal today, /hr for 40hr/week would not pay the term and tooling. Either way, either way the part price is . Two factors influence machining expenses: the upfront cost of a CNC machine and its expected yearly usage, typically around 5000 hours. Machinists determine machine shop rates, commonly known as the machining charge per hour, by dividing the price of CNC machines by their total yearly usage hours.In this guide, we have explored the various factors that influence CNC machine shop rates and discussed different pricing models that manufacturers may employ. Additionally, we have provided valuable insights into optimizing costs and shared real-life case studies showcasing successful cost reduction strategies.

cnc machining cost

What is the red wire for when installing a ceiling fan? The red wire in a ceiling fan usually powers the light in the fan. The red wire usually connects the light to an electric switch that is used to turn the fan off and on. When a red wire is present, this means that the light and the fan can be turned on independently of each other.

average cnc machine shop rate|machine shop hourly rate